iso 9001 work instruction template

ISO 9001 is an international standard that outlines requirements for a quality management system (QMS) to ensure organizations meet customer and regulatory needs. It emphasizes a process-oriented approach, continuous improvement, and customer satisfaction. Work instructions, on the other hand, are detailed, step-by-step documents that guide employees in performing specific tasks. They are essential for ensuring consistency, compliance, and efficiency in operational processes.

Work instructions are optional but highly recommended for organizations aiming to align with ISO 9001 standards. They provide clear, actionable steps, reducing errors and ensuring tasks are completed as intended. By integrating work instructions into a QMS, companies can streamline operations, enhance productivity, and maintain high-quality outputs consistently.

Together, ISO 9001 and well-structured work instructions create a robust framework for achieving operational excellence and customer satisfaction. This combination ensures that processes are not only standardized but also adaptable to evolving business needs.

1.1 What is ISO 9001?

ISO 9001 is an international standard that outlines the requirements for a quality management system (QMS) to ensure organizations meet customer, regulatory, and statutory requirements. It is part of the ISO 9000 family of standards, which focuses on quality management and is designed to help organizations ensure that their products or services consistently meet quality expectations.

Published by the International Organization for Standardization (ISO), ISO 9001 is one of the most widely recognized and implemented quality management standards worldwide. It is based on seven key principles: customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management. These principles provide a framework for organizations to build a robust QMS that aligns with their business goals and objectives.

ISO 9001 is not industry-specific; it can be applied to any organization, regardless of size or sector. Whether a company is involved in manufacturing, services, education, or healthcare, the standard provides a flexible framework to improve operational efficiency, reduce waste, and enhance customer satisfaction. By implementing ISO 9001, organizations demonstrate their commitment to delivering high-quality products or services while continuously improving their processes.

The standard emphasizes a process-oriented approach, which means it focuses on managing and improving end-to-end processes within an organization. This approach ensures that all activities within the QMS are interconnected and aligned with achieving customer satisfaction and business success. Additionally, ISO 9001 promotes a culture of continuous improvement, encouraging organizations to identify areas for enhancement and implement corrective actions to address any non-conformities.

ISO 9001 is divided into several key sections, including the scope, normative references, terms and definitions, and specific requirements. The standard requires organizations to establish documented information, such as policies, procedures, and records, to demonstrate compliance. It also mandates regular internal audits and management reviews to ensure the QMS remains effective and aligned with the organization’s objectives.

One of the key benefits of ISO 9001 is its focus on customer satisfaction. By implementing the standard, organizations can better understand customer needs, improve communication, and deliver products or services that meet or exceed expectations. This, in turn, can lead to increased customer loyalty, improved reputation, and ultimately, business growth.

ISO 9001 also places a strong emphasis on leadership and employee engagement. Leaders are expected to demonstrate commitment to the QMS by establishing a quality policy, assigning responsibilities, and providing the necessary resources to support quality initiatives. Employees at all levels are encouraged to participate in improvement activities, contributing to a more inclusive and motivated workforce.

By aligning with ISO 9001, organizations can establish a solid foundation for delivering high-quality products or services while fostering a culture of excellence and continuous improvement. This standard is not just about compliance; it is about creating long-term value for customers, employees, and stakeholders alike.

Overall, ISO 9001 serves as a globally recognized benchmark for quality management, enabling organizations to stand out in competitive markets and build trust with their customers and partners. Its widespread adoption is a testament to its effectiveness in driving operational excellence and business success.

1.2 What are Work Instructions?

Work instructions are detailed, step-by-step guides that outline the specific actions employees must take to complete a task. They are essential for ensuring consistency, quality, and compliance within an organization, especially in the context of ISO 9001. Unlike procedures, which provide a broader overview of a process, work instructions focus on individual tasks, offering precise directions for each step involved. This specificity helps reduce errors and ensures that tasks are performed uniformly across the organization.

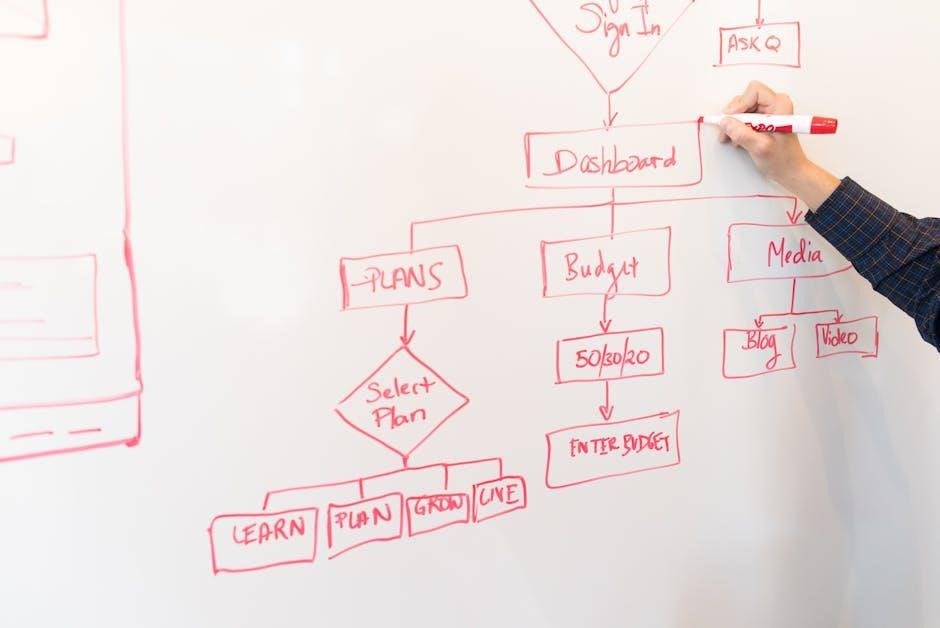

Work instructions typically include essential elements such as the job title, tools or equipment required, safety precautions, and sometimes visual aids like diagrams or flowcharts to enhance clarity. They serve as living documents that can be updated as processes evolve or as feedback is incorporated, aligning with ISO 9001’s emphasis on continuous improvement. While ISO 9001 does not explicitly require work instructions, they are a valuable tool for achieving compliance with the standard’s requirements.

Organizations often use standardized templates to create work instructions, ensuring consistency in format and ease of use. These templates might include sections for purpose, scope, step-by-step procedures, responsibilities, and necessary resources. Work instructions also play a role in employee training, helping new hires understand expectations and procedures. They can serve as reference materials during audits, demonstrating an organization’s commitment to structured and consistent operations.

While work instructions offer numerous benefits, such as supporting a culture of quality and reducing variability, they require regular maintenance to prevent them from becoming outdated. Additionally, overly rigid instructions might hinder innovation if employees feel constrained from deviating. However, the advantages of clear, detailed work instructions—enhanced quality, consistency, and compliance—make them a crucial component of effective quality management systems.